Steel Work

Steel Work Process

Stainless Steel

The steel work that Purex use includes a variety of different grades of stainless steel, specifically 430 and 316. These grades are known for their durability and resistance to corrosion, making them ideal for various applications. In addition to stainless steel, mild steel is also used, particularly for units that are to be powder coated. Powder coating provides a durable and attractive finish, enhancing the aesthetic appeal of the units

Filters

The filters used in the process are made of milled stainless steel or Zintec. Milled stainless steel offers excellent strength and durability, while Zintec is known for its superior corrosion resistance.

Processes

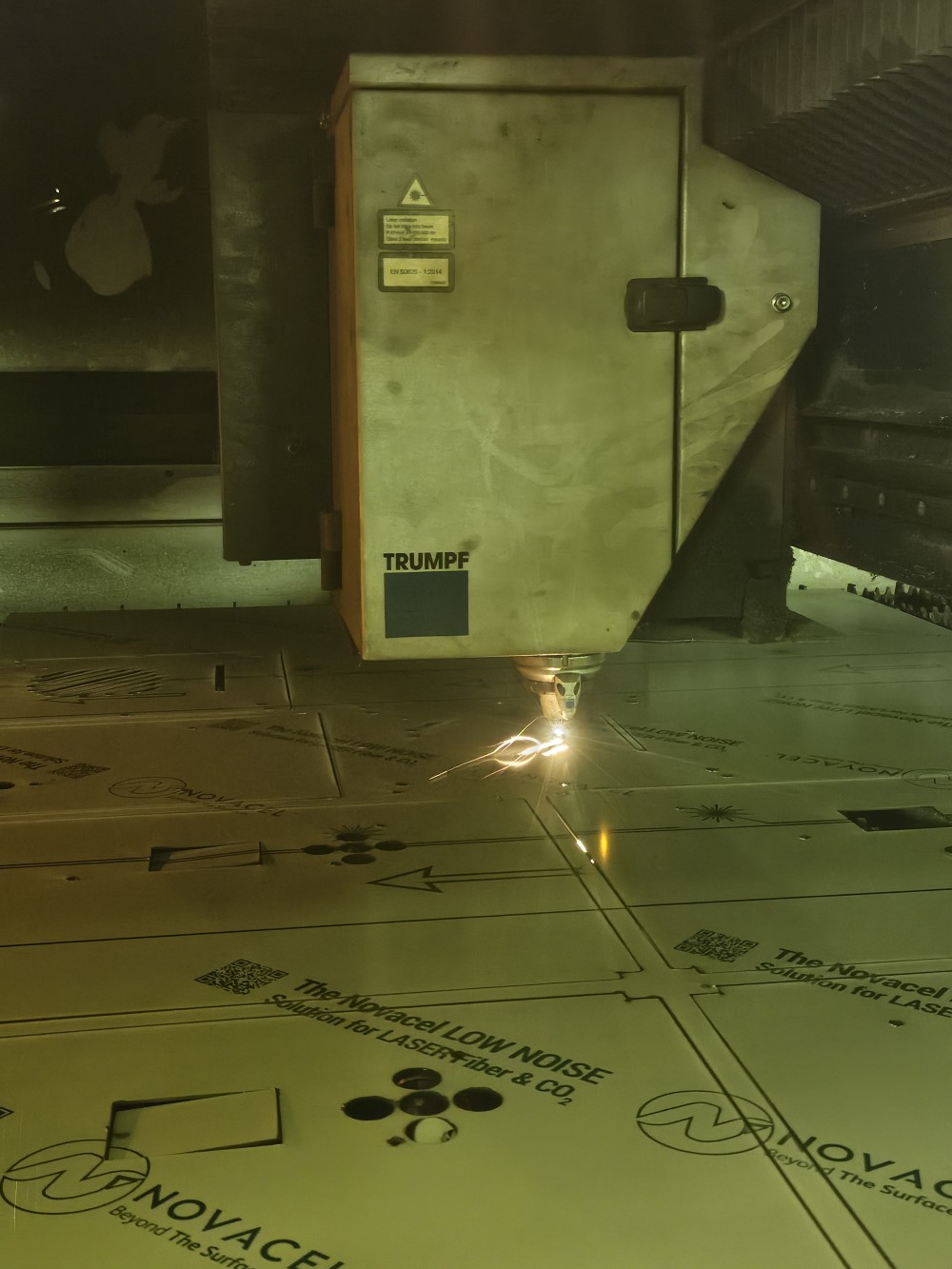

The manufacturing process of the steel units involves several steps. It starts with a flat sheet of steel, which is then cut into the desired shape using a laser cutter. The cut pieces are then formed on a press brake, a machine tool for bending sheet and plate material.

Welding

After the pieces have been formed, they are joined together using spot welding and MIG (Metal Inert Gas) welding techniques. Spot welding is a type of electric resistance welding used to weld various sheet metal products. While MIG welding is a semi-automatic or automatic arc welding process, a continuous and consumable wire electrode and a shielding gas are fed through a welding gun.

Purex Finish

Once the welding process is complete, the units are dressed with a signature grained finish from Purex. This finish not only enhances the appearance of the units but also provides additional protection against wear and tear.

Sealant, Seals And Accessories

Finally, the units are assembled with a secure sealant, seals, and accessories. The sealant helps to prevent leaks and ensure a tight fit, while the seals and accessories provide the finishing touches to the units. This meticulous process ensures the production of high-quality steel units that meet the highest standards of craftsmanship and durability.

Need help choosing?

Speak to a member of our expert team to help choose the most suitable machine for your requirements.