Filters

Purex utilise HEPA and activated carbon filters to provide clean air, below we explain what these filters are and how they work.

HEPA Filters

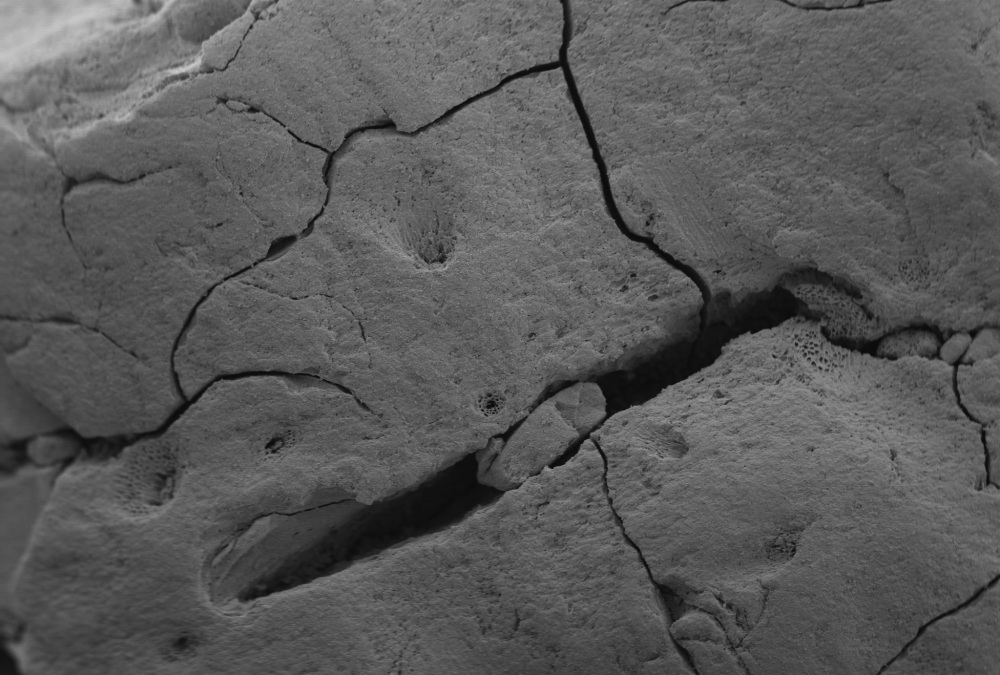

HEPA filters, which stands for ‘High-Efficiency Particulate Air’ is a filter encased in a powerful, zinc-coated steel frame that ensures unmatched strength and durability. Our Purex HEPA filters are fabricated with accuracy from borosilicate fibres, a material akin to glass, and are precisely arranged in a dense matrix.

These filters vaunt an impressive particulate removal performance of 99.97% at 0.3 microns. The size of each HEPA filter varies, offering a substantial filtration area measured in square metres. This ensures that our filters are versatile and can cater to a wide range of requirements.

Purex HEPA filters are a multi-layered defence system against airborne particles and chemicals, making them an essential component in maintaining clean and healthy indoor air.

How HEPA Filters Work

HEPA 'High Efficiency Particulate Air' filters are a powerful tool for enhancing the quality of indoor air. These filters are characterized by their ability to eliminate 99.97% of particles that are 0.3 micrometres or larger.

The operation of these filters involves forcing air through multiple layers, each designed for a specific filtering function. The HEPA layer, typically composed of densely packed borosilicate fibres, are responsible for trapping particles. It does this through the several key methods which remove particulate matter (PM). Particles such as dirt, dust, moisture, bacteria, submicron aerosol.

Our Filters are a refine system where micron-sized particles comply to the filter fabric fibres. Despite the particles being significantly smaller than the spaces between the fibres in the fabric matrix, they are efficiently captured. This is due to their motion in the airstream and the electrostatic attraction between the particles and the fibres.

Activated Carbon

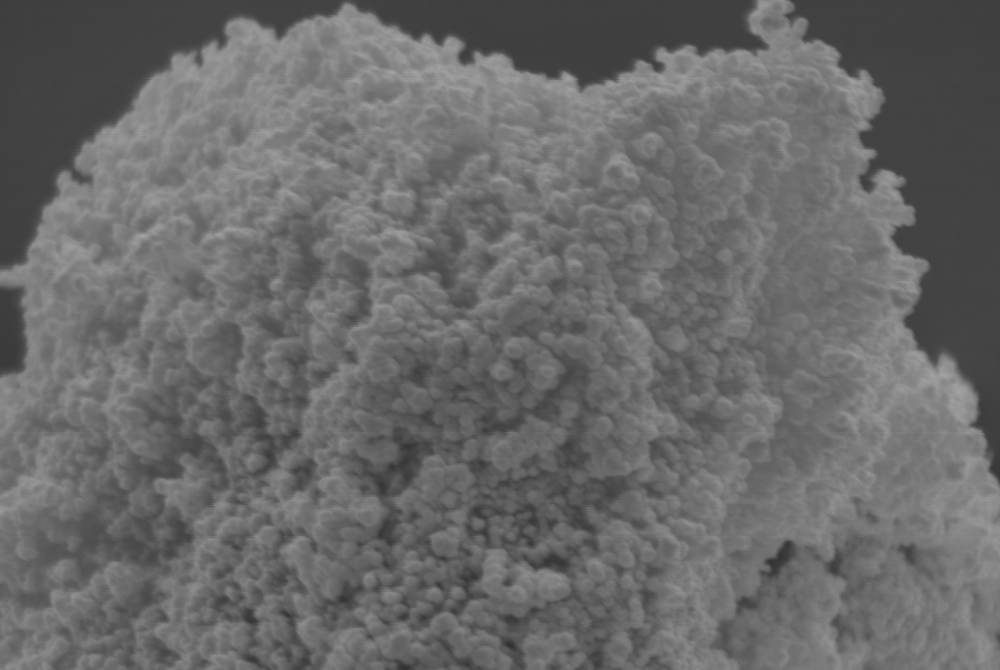

Activated Carbon, is usually derived from waste products such as coconut husks, wood, coal, and other carbonaceous material. These raw materials are converted into charcoal through a process known as activation. Activated Carbon, once treated with either alkali or acid chemicals, gains the ability to adsorb gases and vapours due to its extensive surface area. The range of adsorption varies depending on the specific type of carbon used.

The effectiveness of this adsorption process is largely dependent on the type of carbon used and is most efficient for gases with boiling points greater than ambient temperature. It is particularly suitable for most Volatile Organic Compounds (VOCs) with boiling points between 37°C and 260°C.

How Activated Carbon Works

Activated Carbon adsorption is a process where substances, known as adsorbates, stick to a surface, or adsorbent. There are two main types: physical adsorption and chemisorption, differentiated by the interaction between the adsorbate and adsorbent.

Physical adsorption is a process where organic molecules attach themselves to the surface and pores of the adsorbent due to weak attractive forces. This form of adsorption, which encompasses methods like pressure swing adsorption (PSA) and thermal swing adsorption (TSA), is characterized by its speed and reversibility. The forces involved in this process are the same ones that cause molecules to be attracted to each other in a gas or liquid.

Activated Carbon, a common material in filters, is particularly good at trapping harmful chemicals like Volatile Organic Compounds (VOCs). These VOCs are drawn to the carbon’s surface where they become stuck, a process known as adsorption. Once the carbon’s surface area is fully occupied, it can’t capture any more VOCs.

Moisture is an important factor in adsorption. Typically, any water on the activated carbon is displaced by organic vapours. However, water vapour can compete with VOCs for adsorption sites on the carbon’s surface, which isn’t ideal. Activated Carbon is a great choice for high-capacity.

Need help choosing?

Speak to a member of our expert team to help choose the most suitable machine for your requirements.