Steel Fabrication Services

At Purex, our team of specialists excel in the manufacturing of steelwork. Equipped with the skills and experience to handle a variety of projects, we guarantee precision and quality in every job. Whether you need custom fabrication, structural steelwork, or specialised components, trust Purex with your steel manufacturing solutions.

Our Steel Fabrication Process

Our Steel Manufacturing Processes

As steel fabrication subcontractors, our process involves several key steps:

- Cutting: We start with flat sheets of steel, which are cut into the desired shapes using precision laser cutters.

- Forming: The cut pieces are then shaped using a press brake, a machine tool designed for bending sheet and plate material.

- Welding: Once formed, the pieces are joined together using spot welding and MIG (Metal Inert Gas) welding techniques.

- Powder Coat & Paint: After the welding process is completed, each unit receives Purex’s signature grained finish. This distinctive finish not only elevates the visual appeal of the units but also offers enhanced protection against wear and tear.

- Assembly: Finally, the product is assembled with secure sealants, seals, and accessories to ensure a tight fit and prevent leaks. These finishing touches enhance the product’s functionality and reliability.

Stainless Steel:

At Purex, we utilise a variety of stainless steel grades, particularly 430 and 316. These grades are renowned for their durability and resistance to corrosion, making them ideal for a wide range of applications.

Our Capabilities

Custom Stainless Steel Fabrication:

- Versatile Fabrication: We can create virtually anything from stainless steel, ensuring high durability and performance.

- Unique Colour Options: Customise your products with a variety of colour specifications to match your needs.

- Tailored Designs: We offer unique styles tailored for specific applications, ensuring both functionality and aesthetic appeal.

- Product Examples: Our portfolio includes trolleys and benches, demonstrating our ability to deliver high-quality, practical solutions. However, we are excited and confident about taking on a diverse range of new projects in the future.

- Mobility Solutions: We can equip your products with castors for easy movement if required.

Adaptable Projects: We can build around existing machine applications or create solutions for general use, providing flexibility and innovation in our designs.

External Steel Fabrication Projects

Our External Achievements:

- Custom External Casing: Bespoke painted steel outer casing for a client's project.

- Trolleys: Custom-designed to accommodate various applications.

- Benches: Durable and functional, tailored to client specifications.

- Floor Stands: Engineered for stability and versatility, meeting our client's diverse needs.

- Major Projects: We have successfully completed a variety of significant projects externally, some projects are as showcased in the photos.

Internal Steel Fabrication Projects

Our Internal Achievements:

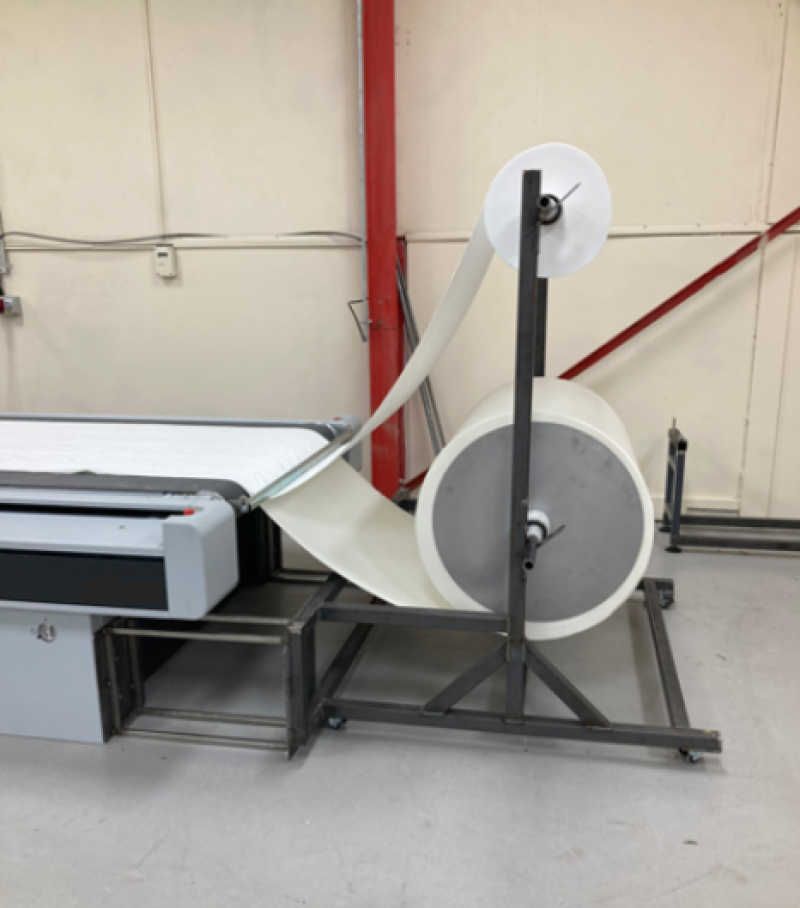

- Bespoke Media Feeder For Cutting Tables: We have engineered black material roll feeders specifically designed for our machines and our multiple sites. These feeders are built to ensure exceptional durability and sustainability, enhancing overall performance.

- Heavy & Light Benches: We have developed a clean and distinctive solid bench, tailored specifically for our new factory. This unique design perfectly meets our needs.

- Major Projects: We have successfully completed a variety of significant projects internally, some projects are as showcased in the photos.

Steel Quality and Standards

Maintaining the highest quality standards for our steel is crucial for ensuring the integrity and reliability of our products. By adhering to industry standards and meeting specific steel specifications, we guarantee the performance and compatibility of our end products with various manufacturing processes. Rigorous quality control measures are implemented throughout the production process to ensure consistency and reliability from start to finish.

By choosing Purex, you can be confident in the quality and precision of our steel manufacturing processes, ensuring that your projects meet the highest standards of excellence.

With our certifications in BS EN ISO 14001:2015 and BS EN ISO 9001:2015, we are qualified for the design, manufacture, and supply of fume purification equipment, as well as the management of installation and servicing.

Testimonial

‘We received the bench on time, thank you greatly.

The bench looks very good, excellent quality, built to a very high standard.

Please let all involved know, keep up the good work.’

Why Choose Us?

Why Choose Us for Subcontracting?

Subcontracting is essential when a project’s requirements are too varied for a single contractor to manage. By subcontracting tasks that fall outside the main contractor’s expertise, we help control costs and reduce overall project risk. Our expertise in the intricate processes and stringent standards of steel manufacturing ensures that we meet the evolving demands of the industry. Understanding these dynamics is crucial for appreciating the economic significance and innovative potential of steel manufacturing.

With our certifications in BS EN ISO 14001:2015 and BS EN ISO 9001:2015, we are qualified for the design, manufacture, and supply of fume purification equipment, as well as the management of installation and servicing.

Benefits of Subcontracting with Us:

- Cost-Effective and Risk-Free: Avoid the high costs and risks associated with purchasing capital equipment that may not meet your needs.

- Expertise and Efficiency: Our engineers are highly skilled and knowledgeable, ensuring that your components meet the highest standards. Benefit from their vast experience to receive world-class service quickly and effectively.

- Focus on Core Business: Let us handle the specialised tasks while your staff concentrate on other key business activities.

- Flexible Commitment: Subcontracting provides the additional resources and expertise you need without the long-term commitment and costs of hiring and training new staff. Use our services as needed, without being tied to lengthy contracts.

- Support for Complex Projects:

There are times when you need assistance for projects that you cannot deliver on your own. Our skills, knowledge, and expertise can make the difference between successfully completing a project and retaining your client, or not.

By choosing us as your subcontracting partner, you gain access to a wealth of expertise and resources, ensuring the success of your projects and the satisfaction of your clients.

Our Quotation Services

Personalised and Unique Specifications:

- Custom Solutions: We offer personalised solutions tailored to your exact specifications, ensuring they meet your unique needs.

- Unique Specifications: We work closely with you to create equipment that fits your specific requirements, no matter how unique.

- Stainless Steel Expertise: As long as the project involves stainless steel, we can collaborate to bring your vision to life, delivering high-quality, custom solutions.

By choosing Purex, you gain access to our extensive expertise in stainless steel fabrication, ensuring that your projects are completed to the highest standards of quality and precision. Let us help you create the perfect solution for your needs.

Enquire about Subcontracting Steelwork

Are you in need of reliable and skilled subcontractors for your steel manufacturing projects? Look no further! Our team specialises in providing top-notch subcontracting services tailored to your specific needs. Get in touch today to learn more!

-

Unit A, Saltgrounds Road,

Brough, East Riding of Yorkshire,

United Kingdom,

HU15 1EG - +44 (0) 1405 746030

- purex@purex.co.uk