The Dangers of ABS Filament Fumes

What is ABS filament?

ABS, also known as acrylonitrile butadiene styrene, is a thermoplastic filament that allows you to print durable 3D parts that can withstand plenty of wear and usage. It is a stiff 3D material that is impact and heat-resistant. In a raw form, ABS material is white in colour.

The neutral colouration can be easily dyed during the manufacturing process to your desired colour. Common uses for ABS include manufacturing materials which are built to withstand high mechanical stress, moving parts and end-use tools.

Are ABS filament fumes toxic?

Although ABS filament fumes are not considered toxic, they are unpleasant to most users. As the material is heated in a 3D printer, it creates gas and microscopic particles during the process. This exudes fumes that can cause physical discomfort such as drowsiness, eye irritation, nausea and headaches.

The particles and gases produced can often be impurities that are then dispersed around the air surrounding the system. The fumes from plastic are often carcinogenic and can cause acute irritation to the respiratory system. If material is processed under prolonged exposure to high temperature or flame, thermal burns to the skin can occur.

How can a 3D printer fume extractor help?

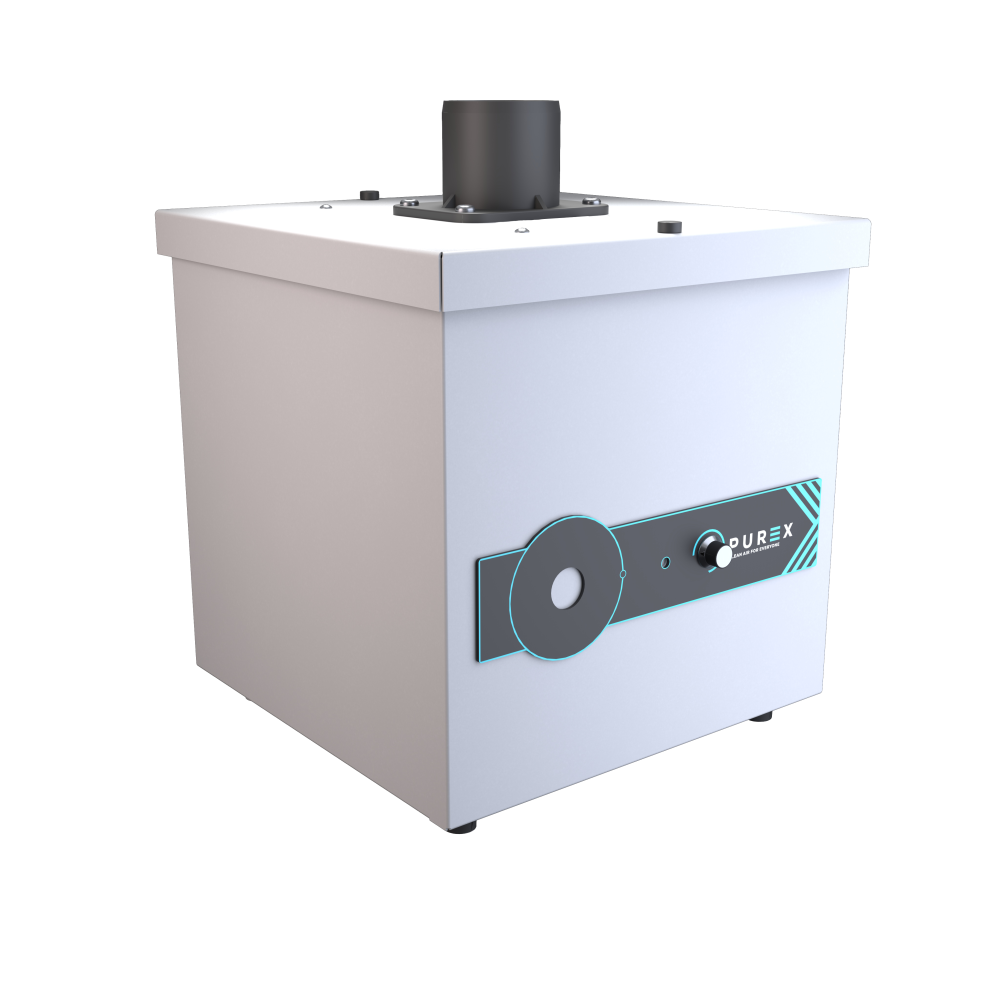

Though ABS filament fumes are generally not toxic, it is recommended that the room in which the 3D printer is operating should be ventilated well or a suitable 3D printing fume extraction system such as the Purex Cub3d be put in place. There are many benefits of using a 3D printer fume extractor, such as;

Health and safety regulations – adhering to the COSHH 2002 (Control of Substances Hazard to Health) which refers to the exposure of dust, harmful gases and fumes in the workplace as a key part of their regulations.

Employee wellbeing – removing unpleasant or harmful fumes within the work environment can avoid any potential health problems, producing better working conditions for employees.

Environmental factors – filtering and extracting harmful fumes positively impacts not only employee health, but also the environment. Fumes that are only extracted and not filtered will affect the environment elsewhere, which is why the process of filtering is just as important.

Less downtime – harmful fume can also damage products and equipment in the work environment. This could then lead to considerable downtime when replacing the equipment or products.

Fume extractors for 3D printing with Purex

Looking to find out more about how fume extraction systems can benefit your 3D manufacturing company?

At Purex, we provide an unparalleled level of service and support – including our 24-hour technical support service, start-to-end projects and response times. Get in touch with our expert team today to find out more about 3D print fume extractors. Alternatively, check your existing 3D fume extraction system by booking an LEV Test with our team.

Latest insights

-

How Fume Extraction Improves Workplace Health and Safety

We all know that health and safety is paramount in the workplace. But how do fume extraction systems improve this? In our guide, we’ll explain h... Read more -

How Does A Laser Cutter Fume Extractor Work?

Where are you right now, and what can you see around you? Perhaps you can see a lamp, table and chairs – or maybe you can spot jewellery, tools... Read more -

Protecting Welders from Harmful Fumes

Designed to fuse materials, welding is a fundamental process in manufacturing and engineering industries. However, welding can also expose workers to... Read more

How Purex can help

We provide an excellent level of service and support, including our 24-hour technical support service and start-to-end projects. Get in touch with our expert team today to find out more.