Stratasys H350 Printer - Case Study

Purex invites you to explore our detailed case study on the Stratasys H350 printer. Our commitment to provide personalised support that meets the unique needs of each customer, resulting in enhanced satisfaction and loyalty.

Company Overview

Company Details: +90 3D Digital Factory

Established: 2005

Services and Industry Position: At +90 3D Digital Factory, we have been providing design and manufacturing solutions for prototypes, pre-series parts, and end-use products since 2005. We support companies engaged in product development and production with our professional and advanced technological manufacturing methods. In addition to our 3D manufacturing service, which boasts the highest production capacity in Eastern Europe and the Middle East, we offer traditional production methods and post-processing services such as CNC machining, silicone molding, and injection molding.

Project Overview

The initial challenge we faced was the installation of an incorrect air extraction system that did not meet the specific requirements of our Stratasys H350 3D Printer. This mismatch led to inefficiencies and potential operational issues.

By identifying and addressing this problem, we were able to implement a solution that ensured optimal performance and reliability for our 3D printing operations.

Problem Identification

Previously, our customers air extraction system lacked several critical components: a HEPA filter, automatic flow control, and gas & particle sensors. These elements are essential for maintaining stable air intake from the printer, ensuring both efficiency and safety.

Project Solution: Enhancing Air Extraction Systems for Optimal Printer Performance

Solution Implementation

To address this issue, we took the following steps:

- Problem Analysis: We identified the missing components and their impact on the system’s performance.

- Equipment Validation: We rigorously validated equipment that met both site and printer requirements.

- Rapid Deployment: We ensured the swift delivery and installation of the validated equipment to minimise downtime.

By implementing these measures, we successfully enhanced the air extraction system, ensuring it meets the highest standards of performance and reliability.

Why Choose Purex

Client Recommendation

We chose the Purex ventilation system based on a strong recommendation from our machine manufacturer, Stratasys. Their endorsement gave us confidence in Purex’s capabilities and reliability.

Exceptional Communication

Our experience with Purex was marked by excellent communication. The entire Purex team, particularly Jack Carr, was highly attentive and focused on resolving our issues swiftly. Their proactive approach ensured that our needs were met promptly and effectively.

Strong Recommendation

We would absolutely recommend Purex. The team’s dedication to problem-solving and their attentive service were outstanding. Additionally, the Purex system has proven to be highly reliable, operating stably for over 72 hours of continuous use. The filter indicators are particularly useful, helping us determine the optimal maintenance periods.

By choosing Purex, we have ensured a stable and efficient ventilation system that meets our high standards of performance and reliability.

Customer Input

“It’s hard to explain how stress-relieving it is to no longer have a chronic problem that hasn’t occurred even once since.”

(Serkan BOSTANCI, Application Engineer)

Machine, Products and Services Used

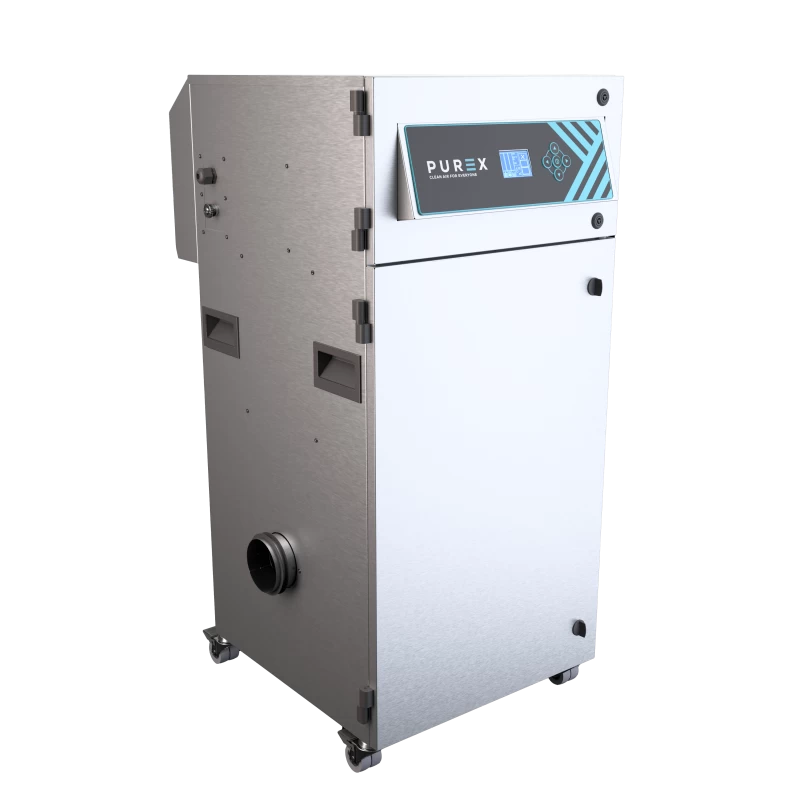

For the ventilation needs, we utilised the Purex 9000-800i 3 Tier system. This advanced equipment was chosen for its superior performance and reliability.

Decision Timeline

The decision-making process took approximately one to two weeks. During this period, our customer carefully evaluated their options to ensure we selected the best solution for their requirements.

By opting for the Purex 9000-800i 3 Tier system, this has significantly enhanced the operational efficiency and air quality standards.

Need help choosing?

Speak to a member of our expert team to help choose the most suitable machine for your requirements.