Soldering in an education setting

What Did The Customer Need?

The customer is a leading provider of technical training in the UK, their aim is to create the next generation of engineering talent whilst upskilling and reskilling existing workforces. They want to help ensure that the Great British manufacturing sector can remain competitive on the global stage. Something that Purex is also passionate about, and we remain proud to have a full manufacturing process in the UK.

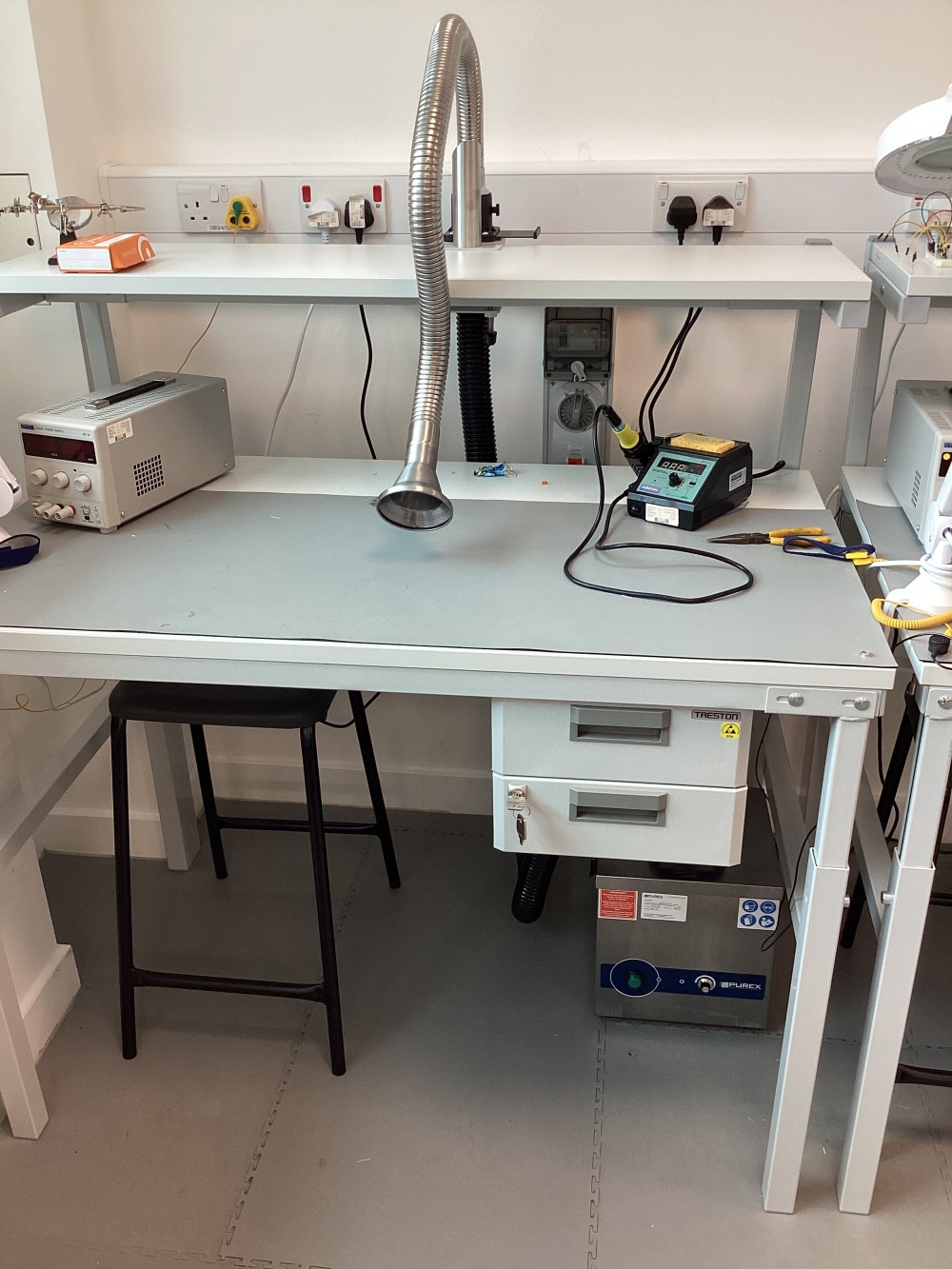

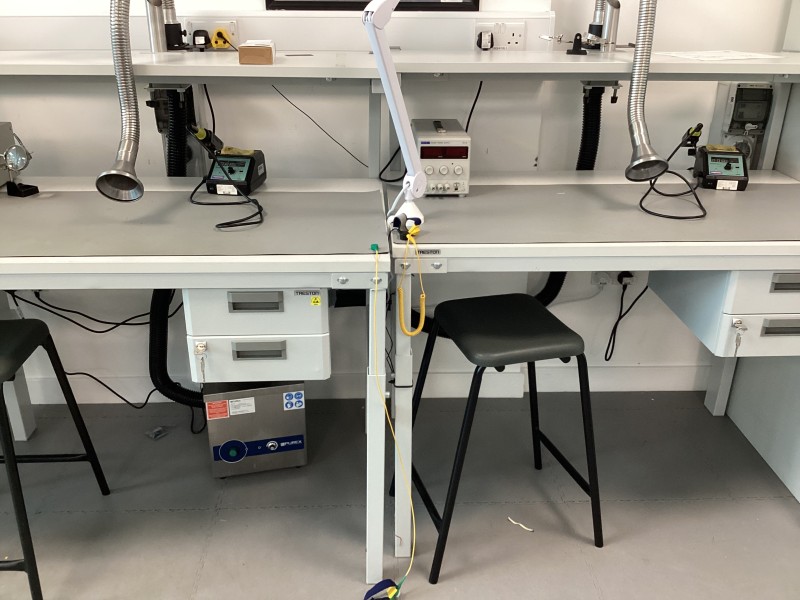

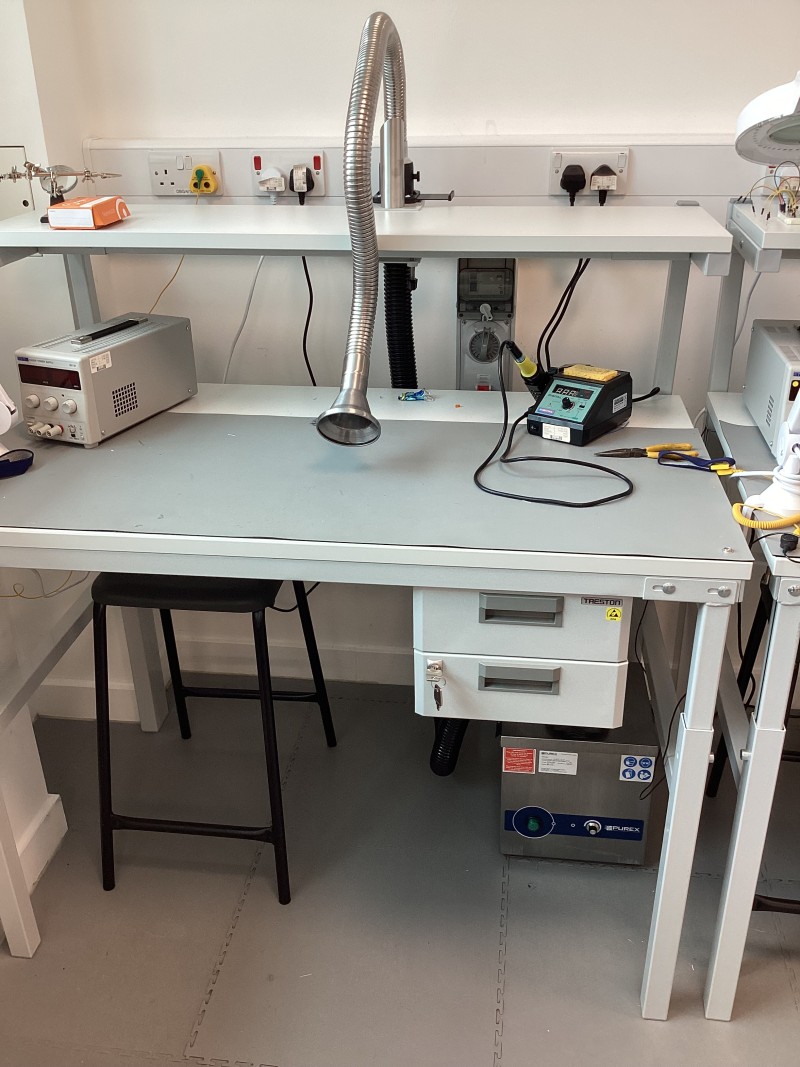

The customer has several stations where they needed to be able to train students on the methods of electrical circuitry. As part of this process allows the students to design their own circuit boards, they wanted to take this one step further and allow the students to make the circuit boards they had designed to confirm the design worked.

During the customers assessment of allowing the students to carry out this addional step, they understood that they would need to provide adequate control of the solder fumes being created by the soldering process. They wanted to have a solution which can be installed in the current work stations. Provide extraction and filtration of the solder fume, allow different amount of stations to be used depending on amount of students working.

What Was The Solution?

Purex discussed with the customer and after reviewing the assessment they had carried out, we agreed that it was important to supply local exhaust ventilation (LEV) to the work stations.

The customer was keen to have the flexibility to potentially move the systems in the future which is why they contacted Purex. They had seen on our website and found that we manufactured high quality, stainless steel independent units and were keen to find out more.

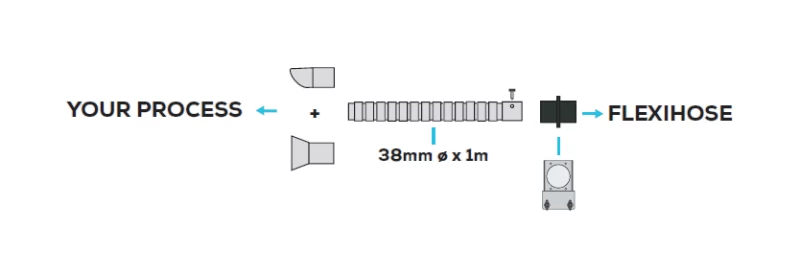

When we explained our manufacturing facilities was based inside the UK and that all Purex products are made within the UK, the customer was thrilled to choose us. We supplied and installed the single arm Fumecube Units, with 100295 kits. This allows the customer to push the arm away from the bench when soldering is not taking place, allowing the bench to be used as normal. When the arm is required then the user can turn the extraction on and place close to the soldering iron as they work. These units where supplied, installed and commissioned by Purex and a commission report for HSG 258 standards, was issued to the customer.

Since this install, the customer has contacted us to provide additional filtration services for a separate process inside the facility.

We are pleased to have helped this training provider and look forward to helping them continue to educate and ensure that the Great British manufacturing sector can remain competitive on the global stage.

Purex Machines And Component Used

-

Fumecube

Find out more -

100295

Find out more

Need help choosing?

Speak to a member of our expert team to help choose the most suitable machine for your requirements.