Dust Extraction Solution

During the set up of our fabrication facility we had our own dust extraction requirements to resolve. During the fabrication of our metal work, we use linishing machines to remove any welding needed during the fabrication process and provide a high quality finish to the metal work. With numerous grinding stations, we faced significant challenges related to airborne dust, which poses health risks to workers and affects the quality of our finished products. We needed a robust dust extraction solution to ensure a safe and efficient working environment.

Challenge

The metal grinding process generates substantial amounts of fine metal dust and particulates, which can have severe implications:

Health Risks: Prolonged exposure to metal dust can lead to respiratory problems, skin irritation, and other serious health issues for employees.

Product Quality: Dust accumulation can compromise the quality of the metal products, leading to defects and increased rework.

Equipment Longevity: Accumulated dust can damage machinery and reduce its operational lifespan, leading to increased maintenance costs and downtime.

Solution

Working with our LEV installation team and the fabrication team to ensure production remained unaffected, we designed and provided a comprehensive solution. Including the supply and installation of high-efficiency dust extraction units.

Key Features of the Solution

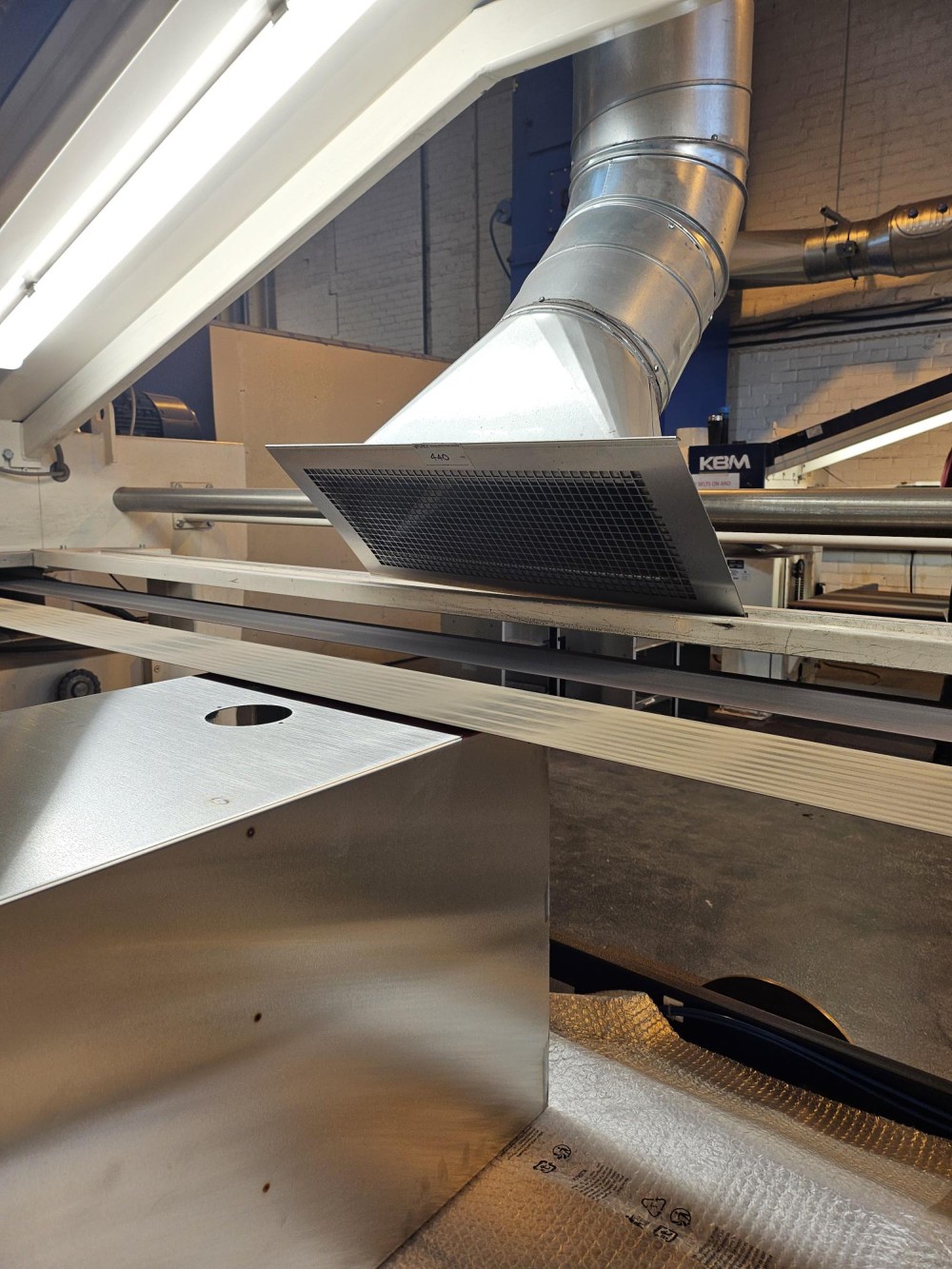

Advanced Dust Extraction Units: Purex supplied several high-performance dust extraction units designed to capture fine metal dust at the source. These units featured powerful suction capabilities and efficient filtration systems to ensure clean air.

Centralised Control System: The system included a centralized control interface, enabling seamless monitoring and adjustment of the dust extraction units. This ensured optimal performance and energy efficiency.

Robust Filtration: The extraction units were equipped with multi-stage filtration systems, including HEPA filters, to capture even the finest dust particles, ensuring a healthier working environment.

Implementation

The implementation process was meticulously planned and executed to minimise disruption to our operations:

Initial Assessment: We conducted a thorough assessment of the working area, identifying specific needs and challenges associated with each grinding station.

Custom Design: Based on the assessment, Purex designed a custom dust extraction solution tailored to the specific requirements of the metal grinding processes.

Seamless Installation: The dust extraction units were installed during normal working hours. However, by working with the fabrication team we were able to schedule for when these work area’s where unused. This ensured no drop in productivity from the fabrication site. The installation was completed efficiently and within the projected timeline.

Comprehensive Training: The LEV installation team provided extensive training for the staff, ensuring they were well-versed in operating and maintaining the new dust extraction system.

Results

The implementation of Purex’s dust extraction system delivered significant benefits for our Fabrication site;

Enhanced Worker Safety: The dust extraction units effectively capture harmful metal dust, protecting our staff from respiratory issues and other health hazards.

Improved Product Quality: With reduced dust contamination, the quality of the finished metal products improved, leading to fewer defects and less time cleaning dust residue.

Increased Equipment Longevity: The dust extraction system helped prevent dust-related damage to machinery, reducing maintenance costs and downtime.

Operational Efficiency: The centralised control system allowed for easy monitoring and adjustment, optimising the performance and energy efficiency of the dust extraction units.

Conclusion

Purex's dust extraction solution provided our fabrication team with a reliable and efficient way to address the challenges of metal grinding dust. By focusing on safety, compliance, and product quality, Purex helped create a healthier and more productive workplace for our staff and help ensure clean air for all.

Need help choosing?

Speak to a member of our expert team to help choose the most suitable machine for your requirements.