Partial Enclosure For Dental Moulds

What Did The Customer Need?

The customer had a process where they created teeth molds and then needed to carry out some manual adjustments to these molds.

This process was carried out with multiple different tools which created a cloud of dust and spread back out into the workplace. Previously the dust was controlled by members of staff wearing PPE and were extensively cleaning the products after working on the molds.

Based on the small nature of the teeth molds they wanted multiple small areas so that during different production levels they could fluctuate the amount of people working on these areas.

What Was The Solution?

Purex carried out a site visit at the premises to confirm what would be the best solution, we considered many subjects such as;

- Budget

- Factory Layout

- Production Flow

- How the work could be carried out with minimum disturbance to production.

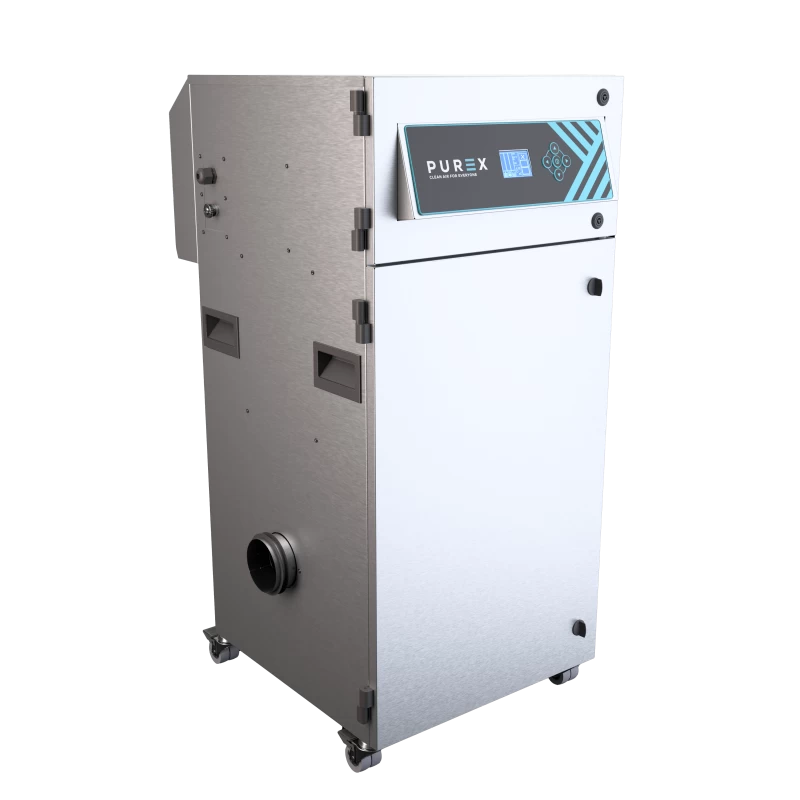

After discussion with the customer, Purex proposed the 800i 2 Tier including customer extraction hoods with intallation and commisioning carried out by Purex's trained engineers.

The customer accepted and within 6 weeks they had a fully installed system signed off and commisoned to HSG 258 specifications. The customer was very pleased with the service levels offered by Purex.

This systems reduced overall costs and the employers could reduce the amount of PPE that was required by the employees and reduce the clean up time of the molds, after the adjustments had been finished.

Purex Machines Used

-

800i 2-Tier

Find out more -

Enclosures

Find out more

Need help choosing?

Speak to a member of our expert team to help choose the most suitable machine for your requirements.