Stratasys H350

Purex installation of equipment with a Stratasys H350

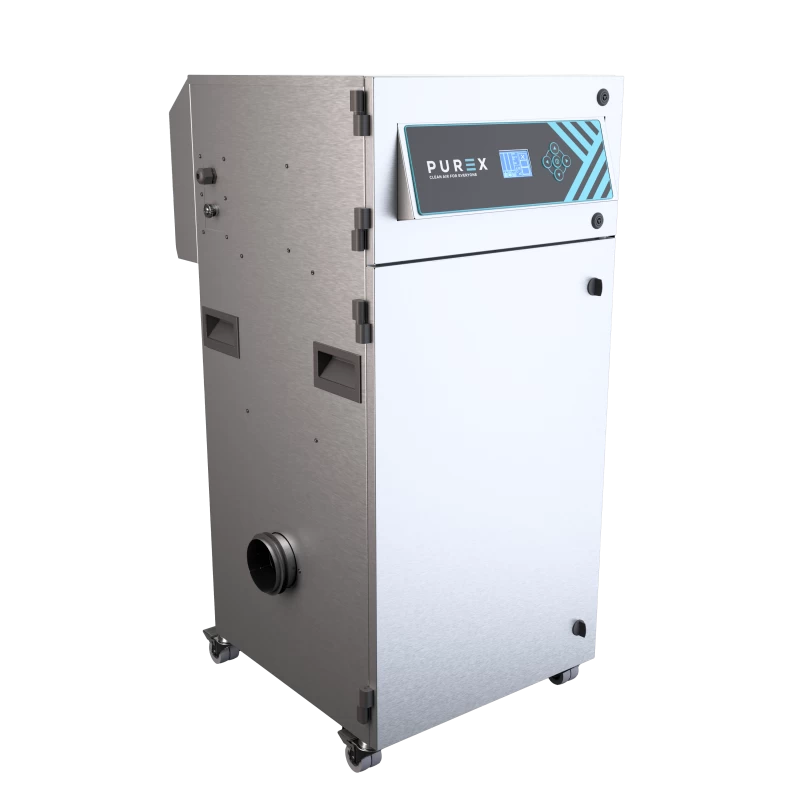

800i with Cyclone for UK customer

Here at Purex, we have over 30 year’s experience supplying fume extraction solutions across a range of industries including additive manufacturing and laser engraving. The customer in question had other equipment on site from Purex, and asked us to assist them with their new piece of equipment, the Stratasys H350.

They where excited to have the printer installed and wanted to get using it as soon as possible. They also needed to make sure that the printer would meet Health and Safety regulations for the employees and prevent excessive build up of unused material inside the printer.

After a site visit and reviewing the specifications of the equipment, we selected the 800i 3-tier with a cyclone unit as the optimum extraction units. This selection aims to keep the users safe and allow them to benefit from higher quality printing.

Why The 800i 3 Tier?

Improved air quality: The Purex 800i 3-Tier filters harmful fumes and particles removing substances from the air and creating a safer working environment. The 3 Tier includes a pre-filter to capture the larger particles and 2 main filters to maximise the filtration inside the unit with activated carbon and Hepa.

Improved air quality: The Purex 800i 3-Tier filters harmful fumes and particles removing substances from the air and creating a safer working environment.

Versatile: As with 3D printing, it’s important to choose a filtration system that can adapt to different printing materials. The 800i 3-Tier can handle fumes from a variety of different printing materials such as ABS, PLA, Nylon and more.

Reduced downtime: Without adequate filtration, impurities and moisture can clog the printer extruder, leading to print failures and extra maintenance on the H350. A proper filtration system reduces the risk of clogs and allows for more efficient printing.

Cost saving: By reducing downtime, print failures and risk of clogs in the system, the Purex 800i 3-Tier can help you to save money by reducing wasted materials and from more efficient printing.

Versatile: As with 3D printing, it’s important to choose a filtration system that can adapt to different printing materials. The 800i 3-Tier can handle fumes from a variety of different printing materials such as ABS, PLA, Nylon and more.

Why the Cyclone Kit?

- Looking to take your filtration to the next level? The Cyclone is a must have for any business looking to extend the life of their Hepa filter while using the H350 3D Printer.

- The Cyclone kit works in conjunction with the 800i 3-Tier to capture large dust and debris from your additive manufacturing process before it reaches your Purex filters and prolongs the filter life.

- The Cyclone works by creating a cyclonic airflow which separates the heavier debris from the lighter dust particles. This removes large particles of debris before they reach your filtration system, enhancing its lifecycle.

What did the customer think?

“We are very pleased with the service that Purex offered us, knowing them from our previously dealings we knew exactly what to expect and Purex delivered. From the initial site visit and to the machine installation, it took 5 weeks, which lined up perfectly with the delivery of our unit. From the sales visit, to final installation, the whole process was smooth and allowed us to get using the printer immediately after delivery which has dramatically helped our production process”

-

800i 3 Tier

Find out more -

Cyclone

Find out more

Contact us with your additive manufacturing needs

-

Unit A, Saltgrounds Road,

Brough, East Riding of Yorkshire,

United Kingdom,

HU15 1EG - +44 (0) 1405 746030

- purex@purex.co.uk