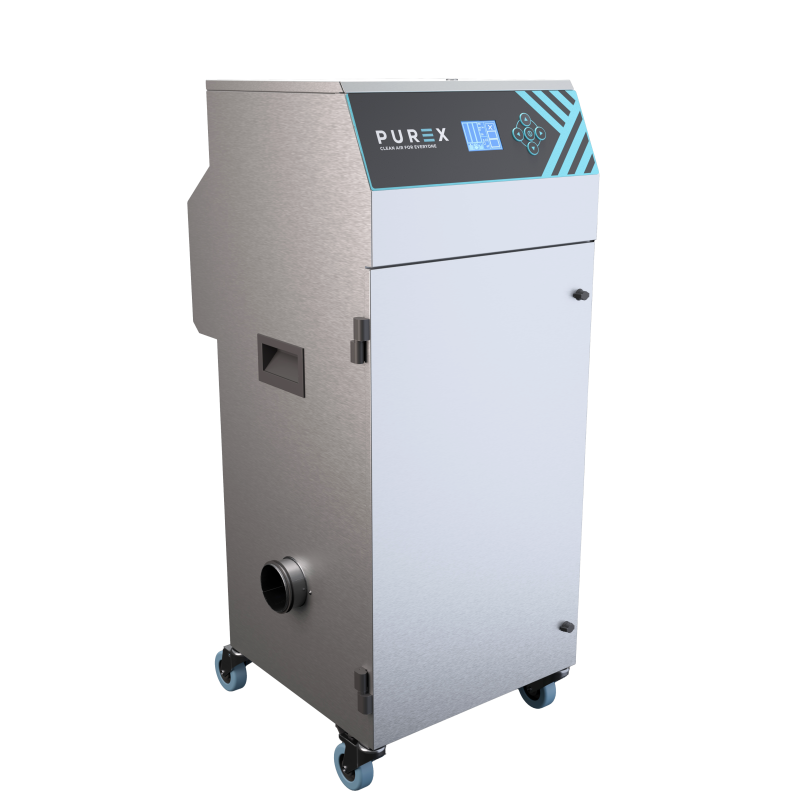

400 Range

The Purex 400i Range is our most well-known extraction range. These machines are equipped with fail-safes to ensure extra protection for the operator and the environment. It comes equipped with high performance motors, gas and particle monitoring as standard and the capability for remote interfacing. The 400i range includes the 400, 400i, and 400i PVC. All units are reliable and are highly recommended across various industries, such as, Coding, Pharmaceuticals/Medical, Forensic Research and Development, Veterinary, Podiatry, 3D Printing, Electronics, and Laser Engraving.

The Purex 400 - A versatile machine for use within the Electronics industries due to its small footprint and powerful air flow abilities.

The Purex 400i - This versatile machine is commonly used in the Laser Engraving and Coding industry, its high extraction rate and compact size make it renown around the world.

The Purex 400i PVC - Designed to tackle harmful corrosive contaminants produced by laser marking PVC parts, Purex PVC units are specially coated to prevent corrosion on the internal surfaces.

The Purex 400I – OZONE – Designed specifically to extract hazardous particles and chemicals produced by Ozone applications, an excellent solution throughout several sectors, including the medical sectors.

The Purex 400i Dye Sub – Designed for the Dye Sublimation process, this unit has a coalescing filter to collect and allow way draining of excess fluid gathered during the process.

Key features

Clear & informative graphic display

The full-colour touch screen display allows for easy control and quick adjustments to airflow.

Automatic electronic flow control

Engineered to maintain a constant extraction rate even as the filter begins to block, ensuring consistent performance and efficiency over time.

Highest grade HEPA and carbon technology

A multi-layered defence system against airborne particles and chemicals, making essential components in maintaining clean and healthy indoor air.

…plus these other great benefits

- Gas and particle sensors to warn the operator

- Quick change patented labyrinth prefilters, which deliver longer filter life

- Specialized coating to prevent corrosion from PVC fumes

Specifications

VOLTAGE

120v - 230vWATTAGE

1.2kWFREQUENCY

50Hz / 60HzCABINET HEIGHT

710mm - 1195mmCABINET WIDTH

465mmCABINET DEPTH

528mmCABINET WEIGHT

50kg - 70kgAIRFLOW

400m3/hSOUND LEVEL

<60dBa-

400i

400i

400i

This versatile machine is commonly used in the Laser Engraving and Coding industry, its high extraction rate and compact size make it renown around the world

-

400

400

400

The 400 is a versatile machine for use within the Electronics industries due to its small footprint and powerful air flow abilities.

-

400i PVC

400i PVC

400i PVC

The Purex 400i PVC - Designed to tackle harmful corrosive contaminants produced by laser marking PVC parts, Purex PVC units are specially coated to prevent corrosion on the internal surfaces.

-

400i Dye Sub

400i Dye Sub

400i Dye Sub

The Purex 400i Dye Sub – Designed for the Dye Sublimation process, this unit has a coalescing filter to collect and allow way draining of excess fluid gathered during the process.

-

400i Ozone

400i Ozone

400i Ozone

The Purex 400I – OZONE – Designed specifically to extract hazardous particles and chemicals produced by Ozone applications, an excellent solution throughout several sectors, including the Medical sectors.

Enquire about the Purex 400 Range

-

Unit A, Saltgrounds Road,

Brough, East Riding of Yorkshire,

United Kingdom,

HU15 1EG - +44 (0) 1405 746030

- purex@purex.co.uk

Find compatible accessories

We have a range of accessories that are compatible with our machines. Please see our accessories page for further information.

View accessoriesNeed help choosing?

Speak to a member of our expert team to help choose the most suitable machine for your requirements.